Views: 0 Author: Onustec Publish Time: 2025-08-26 Origin: Site

Ever wondered how modern manufacturing achieves such precision? Enter the CNC turning center. These machines revolutionize production with unparalleled accuracy. A CNC turning center is a key player in today's manufacturing, shaping industries with its advanced capabilities. In this post, you'll learn about their definition, significance, and the CNC technology behind them.

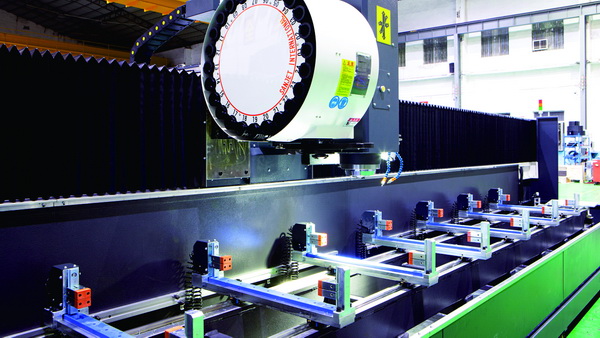

A CNC turning center is a sophisticated machine designed for precision and efficiency in turning operations. Understanding its main components helps clarify how it achieves such high performance, whether it's a vertical turning center, horizontal turning center, or a specialized swiss turning center.

The main spindle is the heart of a CNC turning center machine. It holds and rotates the workpiece at varying speeds, depending on the material and desired finish. In a lathe turning center, the spindle's accuracy directly affects the quality of the final product. Advanced CNC turning centers often feature high-speed spindles with excellent rigidity to minimize vibration and maintain precision.

The tool turret holds multiple cutting tools and indexes them automatically during the machining process. This allows the CNC turning and milling center to switch tools without manual intervention, increasing efficiency and reducing cycle time. Some cnc multi axis turning milling centers have turrets capable of holding a wide variety of tools, enabling complex operations like drilling, grooving, and threading in one setup.

The control panel is the operator’s interface with the CNC turning center. It displays machining parameters, allows for program input, and monitors real-time performance. Modern control panels include touchscreen displays and intuitive software, making it easier to manage complex programs and optimize machining processes. This is essential for manufacturers working with cnc machining centers and turning centers that require precise adjustments and monitoring.

The chuck securely grips the workpiece during machining. Depending on the application, different types of chucks—such as three-jaw, four-jaw, or collet chucks—are used to hold parts firmly. Proper workholding is critical to avoid slippage and ensure dimensional accuracy. Some CNC turn mill center manufacturers offer specialized workholding solutions tailored to specific industries or part geometries.

Tip: Regularly inspect and maintain the tool turret and chuck to prevent downtime and ensure consistent precision in your CNC turning center operations.

A CNC turning center operates by rotating the workpiece against a stationary cutting tool to shape the material. The main spindle spins the part at programmed speeds, while the tool turret moves precisely along multiple axes to perform various cutting actions. This setup allows for continuous and automated turning processes that deliver consistent results. Whether it’s a vertical turning center or a horizontal turning center, the principle remains the same: controlled movement and rotation create the desired geometry.

Turning involves removing material from the outer diameter or inner diameter of a workpiece. Common operations include:

Facing: Cutting a flat surface perpendicular to the spindle axis.

Taper Turning: Producing a conical shape by adjusting the tool path angle.

Threading: Creating screw threads on the surface.

Grooving: Cutting narrow channels or recesses.

Drilling: Performed on some CNC turning and milling centers using live tools.

In a swiss turning center, the workpiece is supported closely by a guide bushing, enabling the machining of small, intricate parts with high precision. Meanwhile, cnc multi axis turning milling centers combine turning with milling operations, allowing complex 3D shapes in a single setup.

The CNC turning center relies on computer programming to control all movements and operations. G-code or other CNC programming languages instruct the machine on spindle speed, tool selection, feed rates, and cutting paths. The control panel interprets these commands and coordinates the main spindle, tool turret, and other components. This automation reduces human error and improves repeatability across production runs.

Programs can be customized for different materials, shapes, and tolerances. Advanced software also simulates the machining process before actual production, minimizing risks of errors or tool collisions. CNC turn mill center manufacturers often provide tailored software solutions to optimize programming for specific machines or industries.

Tip: Use simulation software to verify CNC turning center programs before running the machine to prevent costly mistakes and downtime.

CNC turning centers have revolutionized manufacturing by offering several key advantages over traditional machining methods. Whether you’re using a vertical turning center, horizontal turning center, or a swiss turning center, these machines deliver superior performance that drives productivity and quality.

One of the most significant benefits of a CNC turning center is its exceptional precision. The computer-controlled movements ensure that each cut is made exactly according to the programmed specifications. This accuracy reduces errors and material waste, which is vital for industries requiring tight tolerances, such as aerospace and medical equipment manufacturing.

Advanced CNC turning center machines use high-quality components like rigid spindles and precise tool turrets to maintain consistent dimensional accuracy. For example, a lathe turning center can produce complex geometries with repeatable precision, minimizing the need for secondary finishing operations.

CNC turning centers dramatically increase machining efficiency. Automated tool changes, multiple-axis control, and optimized cutting paths reduce cycle times. This efficiency enables manufacturers to meet tight deadlines and increase throughput without sacrificing quality.

Machines like the cnc multi axis turning milling center combine turning and milling in one setup, eliminating the need to transfer parts between machines. This integration saves time and reduces the risk of misalignment. Additionally, the ability to run unattended or with minimal supervision allows for extended production runs and better use of labor resources.

Modern CNC turning centers are incredibly versatile, capable of handling a wide range of materials and complex part designs. Whether working with metals, plastics, or composites, these machines adapt to various applications.

The flexibility of tool turrets and live tooling options means you can perform multiple operations—turning, drilling, threading, and milling—without changing machines. This versatility is especially valuable for small-batch production or prototyping, where quick setup changes are necessary.

Furthermore, specialized machines like swiss turning centers excel at producing small, intricate components with tight tolerances, making them ideal for medical devices or precision electronics.

Tip: To maximize the advantages of your CNC turning center, invest in regular operator training and update your CNC programs to leverage the latest machining strategies and tool technologies.

CNC turning centers play a vital role across various industries, offering precision, speed, and versatility. Their ability to produce complex parts with tight tolerances makes them indispensable in fields where quality and reliability are paramount.

In the automotive sector, CNC turning center machines are essential for manufacturing components such as engine parts, shafts, and brake components. These machines, including horizontal turning centers and vertical turning centers, deliver consistent precision needed for high-performance vehicles. The automation and speed of CNC turning and milling centers help automotive manufacturers reduce production time while maintaining strict quality standards. Additionally, the versatility of cnc multi axis turning milling centers allows for producing parts with complex geometries in a single setup, boosting efficiency.

Aerospace manufacturing demands the highest levels of accuracy and repeatability. CNC turning centers, especially swiss turning centers and lathe turning centers, are widely used to create components like turbine blades, landing gear parts, and structural elements. The precision control offered by these machines ensures that every part meets rigorous safety and performance criteria. Aerospace manufacturers often rely on cnc machining centers and turning centers that can handle exotic materials and intricate designs, making these machines crucial for innovation and quality assurance.

The medical industry requires components with exact specifications and flawless finishes. CNC turning centers excel in producing surgical instruments, orthopedic implants, and dental devices. Swiss turning centers are particularly suited for manufacturing small, detailed parts used in medical equipment, thanks to their ability to maintain tight tolerances and fine surface finishes. The integration of turning and milling functions in cnc turn mill centers allows manufacturers to complete complex parts in fewer steps, reducing contamination risks and improving throughput.

Tip: When selecting a CNC turning center for industry-specific applications, consider machines that offer material compatibility and precision features tailored to your production needs.

Selecting the ideal CNC turning center for your manufacturing needs involves careful evaluation of several key factors. Whether you’re considering a vertical turning center, a horizontal turning center, or a specialized swiss turning center, making the right choice ensures efficiency, quality, and long-term value.

Part Complexity and Size: Determine the size and complexity of parts you plan to produce. Vertical turning centers excel at handling large, heavy workpieces, while horizontal turning centers are often preferred for smaller to medium-sized parts requiring high precision. Swiss turning centers are ideal for tiny, intricate components.

Machining Capabilities: Assess the types of operations you require. If your production demands both turning and milling, a cnc multi axis turning milling center or a cnc turning and milling center can reduce setup times and improve workflow.

Material Compatibility: Different machines handle various materials better. Ensure the CNC turning center machine you choose can effectively work with your typical materials, whether metals, plastics, or composites.

Automation and Tooling Options: Look for features like automatic tool turrets, live tooling, and advanced control panels. These add versatility and speed, especially when working with complex parts or requiring multi-step operations.

Footprint and Shop Layout: Consider the available floor space and how the machine fits within your production line. Some lathe turning centers have compact designs suited for smaller shops.

Investing in a CNC turning center involves upfront costs and ongoing expenses. Here’s what to keep in mind:

Initial Purchase Price: Prices vary widely based on machine size, capabilities, and manufacturer. High-end cnc turn mill center manufacturers offer machines with advanced features but at a premium.

Operating Costs: Factor in tooling, maintenance, energy consumption, and operator training. Machines with higher automation may reduce labor costs but require skilled programmers.

Return on Investment (ROI): Calculate how the machine will improve production speed, reduce scrap, and increase part quality. Efficient machines can quickly offset their cost through higher throughput and less rework.

Technology evolves rapidly in CNC machining centers and turning centers. To safeguard your investment:

Choose Machines with Upgrade Paths: Select CNC turning centers that allow for software updates, additional tooling, or expanded axis capabilities.

Consider Industry Trends: Machines supporting multi-axis operations or integration with Industry 4.0 systems offer better adaptability.

Supplier Support: Partner with manufacturers known for reliable service, training, and spare parts availability.

Scalability: Ensure the machine can handle increased production volumes or new part designs as your business grows.

Tip: When choosing a CNC turning center, prioritize machines that balance your current production needs with flexibility for future technological advancements to maximize long-term value.

Proper maintenance and timely troubleshooting are crucial for ensuring the optimal performance of your CNC turning center. Whether you operate a vertical turning center, horizontal turning center, or a swiss turning center, regular care helps avoid costly downtime and extends the machine’s lifespan.

Daily Cleaning: Remove chips and debris from the machine bed, tool turret, and chuck area to prevent buildup that can affect accuracy.

Lubrication: Regularly lubricate moving parts such as the spindle bearings, guideways, and ball screws following the manufacturer’s guidelines.

Check Coolant Levels: Maintain proper coolant levels and quality to ensure efficient heat dissipation and prolong tool life.

Tool Inspection: Frequently inspect cutting tools for wear or damage. Replace tools before they cause poor finishes or damage to the workpiece.

Software Updates: Keep the CNC control software updated to benefit from bug fixes and new features that improve machine performance.

Inaccurate Cuts: Often caused by tool wear, spindle misalignment, or worn guideways. Regular calibration and tool replacement can resolve this.

Tool Turret Malfunctions: Can result from debris buildup, mechanical wear, or faulty sensors. Clean the turret regularly and inspect sensors for proper function.

Workpiece Slippage: Usually due to improper chucking or worn jaws. Ensure the chuck is correctly set and jaws are in good condition.

Control Panel Errors: May stem from software glitches or hardware faults. Restart the system, check connections, and update software as needed.

Excessive Vibration: Caused by imbalance in the spindle or loose components. Balance the spindle and tighten mounting bolts to reduce vibration.

To maximize the life of your CNC turning center machine:

Establish a preventive maintenance schedule tailored to your machine type, such as vertical turning centers or cnc multi axis turning milling centers.

Train operators to recognize early signs of wear or malfunction.

Use genuine parts from trusted cnc turn mill center manufacturers for replacements.

Monitor machine performance data to predict and prevent failures.

Avoid overloading the machine beyond its specified capacity.

Tip: Document all maintenance activities and troubleshooting steps to build a reliable history that helps identify recurring issues and improves future machine care.

CNC turning centers are vital for precision manufacturing, offering components like main spindles, tool turrets, and control panels. They ensure accuracy and efficiency in various industries, including automotive and aerospace. Future trends include enhanced automation and integration with Industry 4.0. For optimal performance, regular maintenance is crucial. Companies like Guangzhou Onustec Group Ltd. provide advanced CNC solutions, offering machines that enhance productivity and reliability, ensuring long-term value and adaptability in evolving manufacturing landscapes.

A: A CNC turning center is a sophisticated machine designed for precision turning operations, featuring components like a main spindle, tool turret, and control panel. It automates the process of shaping materials by rotating the workpiece against stationary cutting tools.

A: While both machines perform turning operations, a CNC turning center offers advanced automation, multiple tool turrets, and computer-controlled precision, unlike traditional lathe turning centers which may require more manual intervention.

A: Horizontal turning centers are ideal for high-precision parts, offering stability and efficient chip removal. They are well-suited for small to medium-sized components, providing consistent accuracy and surface finish.

A: Swiss turning centers excel in machining small, intricate components with tight tolerances. They support the workpiece closely with a guide bushing, ensuring precision and reducing deflection during operations.

A: CNC multi axis turning milling centers combine turning and milling in one setup, allowing for complex part geometries to be machined in a single process. This integration reduces setup times and improves workflow efficiency.