Views: 0 Author: Site Editor Publish Time: 2025-12-15 Origin: Site

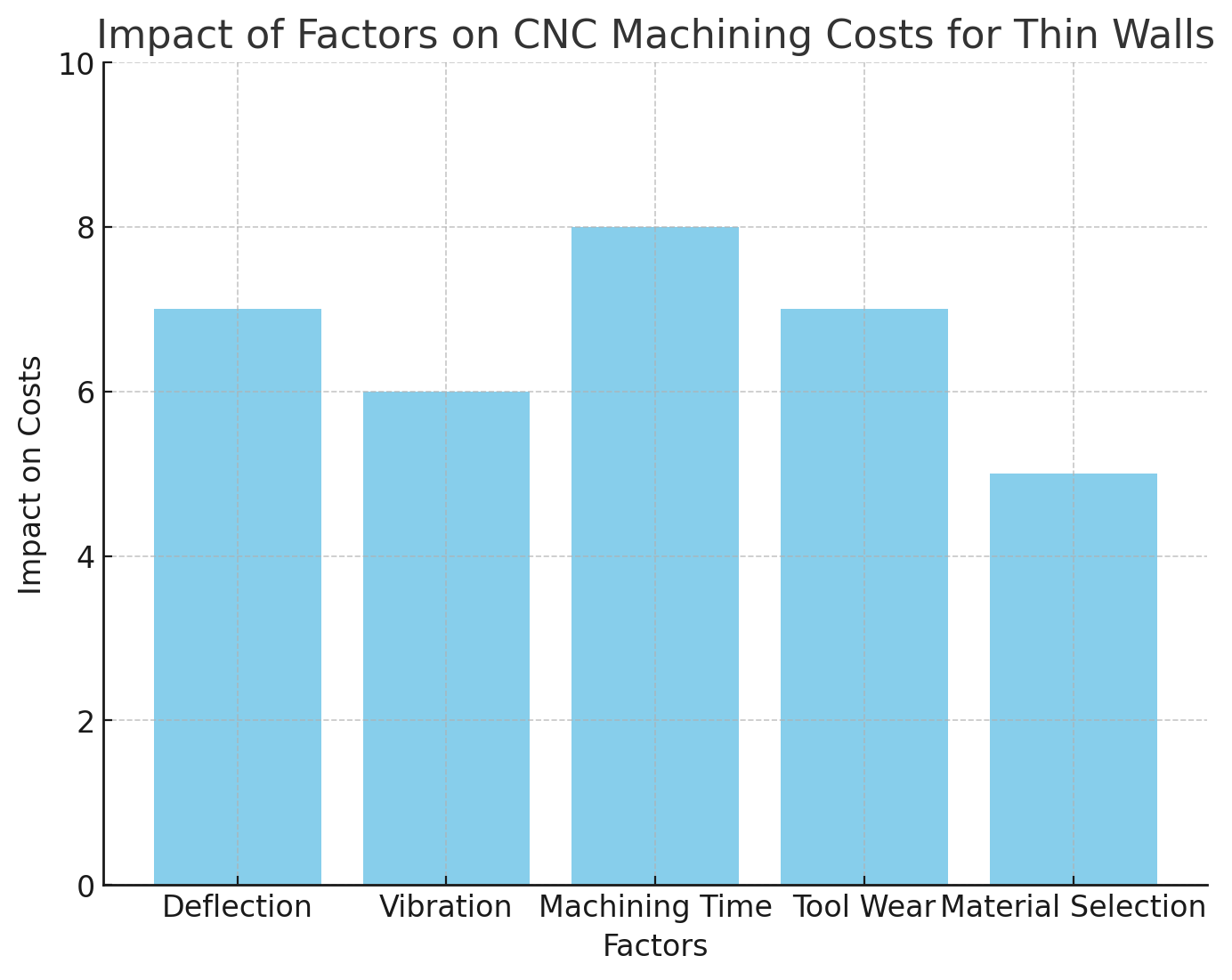

CNC machining is a game-changer in modern manufacturing, enabling the production of highly accurate, complex parts. However, designing thin-walled parts for CNC machining can lead to high costs due to challenges like deflection, vibration, and tool wear.

In this article, we will explore how thin walls impact machining costs and provide practical strategies to reduce these expenses while maintaining part integrity. You'll learn effective design tips, material selection guidance, and machining techniques to optimize your designs for cost efficiency.

One of the primary challenges of machining thin walls is the tendency for deflection and vibration. Thin features are less rigid, which means they can bend under the cutting forces of the CNC tool. As the tool engages with the material, the reduced stability of the thin walls results in vibrations, which can impact the precision of the final part. These vibrations also cause tool wear, slow down the machining process, and lead to surface imperfections, all of which add to production costs.

Challenge | Impact | Solution |

Deflection | Leads to dimensional inaccuracy | Use thicker walls, optimize support |

Vibration | Poor surface finish | Use larger tools, optimize cutting parameters |

Tool Wear | Increased machining time | Use harder materials, larger tools |

Material Deformation | Loss of part integrity | Choose materials with better rigidity |

Thin walls require the CNC machine to make multiple passes with lighter cuts to minimize deflection. This process extends the overall machining time and requires slower cutting speeds, leading to increased operational costs. Additionally, the constant engagement of tools in these delicate areas accelerates tool wear, requiring more frequent tool changes and further raising costs. Over time, this cycle of slow machining and tool replacement can significantly inflate production expenses.

Material selection plays a key role in thin wall CNC machining. Different materials react to the cutting forces in unique ways. Softer materials such as aluminum are easier to machine, reducing the risk of deflection and vibration. However, harder materials like stainless steel or titanium present additional challenges. They may require special cutting tools, slower cutting speeds, and more precise control to manage heat buildup and reduce material distortion. Choosing the right material can help optimize machining time and costs, with softer materials generally offering a better cost-to-performance ratio.

Material | Machinability Rating | Recommended for Thin Walls |

Aluminum (6061) | High | Yes |

Brass (C360) | High | Yes |

Stainless Steel | Moderate | No |

POM (Delrin) | High | Yes |

Nylon | Moderate | No |

To minimize the challenges of thin wall machining, it’s essential to design walls with appropriate thickness and geometry. Designing thicker walls than the typical minimums provides added stability, reducing the risk of deflection and vibration. Additionally, ensuring the correct wall-to-length ratios is critical. A common recommendation is to keep the length of the wall no more than four times the thickness of the wall to avoid instability during machining.

Another way to reduce machining costs is by using larger tools. Larger cutting tools allow for faster material removal and better surface finishes, helping to minimize the number of passes needed. These tools also reduce tool wear and speed up the overall machining process. However, designers must ensure that the part geometry is compatible with the larger tools to avoid interference and ensure precision.

Incorporating internal radii into the corners of parts is another design tip that helps reduce machining costs. Sharp internal corners require smaller tools, which necessitate multiple passes and slower cutting speeds. By adding internal radii that are at least one-third of the depth of the cavity, manufacturers can use larger tools that work faster and more efficiently, reducing both machining time and tool wear.

When designing thin-walled parts, it’s essential to strike a balance between strength and cost. Thicker walls often provide better strength but come at a higher cost due to increased material usage and machining time. However, excessively thin walls can lead to instability and increased machining complexity. The goal is to optimize the wall thickness to ensure the part meets its strength requirements without incurring unnecessary machining costs.

Wall thickness recommendations can vary depending on the material used. For metals, a minimum thickness of around 0.8 mm is usually sufficient to avoid deflection and excessive machining time. For plastics, a minimum thickness of 1.5 mm is typically recommended. Adjusting wall thickness based on the material being used ensures that parts are both cost-effective and durable, avoiding unnecessary rework and tool wear.

Consider a part with a thin wall design where the wall thickness is adjusted from 0.8 mm to 1.2 mm. While the initial design might seem more cost-effective, the adjustments lead to a more stable part during machining, reducing tool wear and machining time. These small changes can lead to significant cost savings over the course of production, proving that optimizing wall thickness is a simple yet effective cost-reduction strategy.

Limiting thread lengths and using standard features is another effective way to reduce machining complexity. Excessive thread lengths can require specialized tools and slow cutting speeds, both of which contribute to higher costs. By sticking to standard drill sizes and limiting thread lengths to no more than three times the hole diameter, designers can reduce setup times and machining costs while maintaining functional performance.

While it’s tempting to add intricate design elements to enhance a part’s functionality or appearance, unnecessary features should be eliminated to reduce machining complexity. Features such as decorative surfaces, fine details, or excessively small holes can add unnecessary machining time and tool wear. By focusing on essential features, engineers can simplify designs and lower costs without compromising the part’s intended functionality.

Tolerance Requirement | Impact on Cost and Time |

±0.1 mm | Minimal increase in cost |

±0.05 mm | Moderate increase in cost |

±0.01 mm | Significant increase in cost |

Multi-axis CNC machines, particularly 5-axis systems, are incredibly effective for machining thin-walled parts. These advanced machines allow for more precise cutting by positioning the part in multiple orientations during a single setup, reducing the need for re-fixturing and improving machining efficiency. Utilizing multi-axis machining not only shortens production time but also improves part quality, making it a cost-effective solution for complex thin wall designs.

Adaptive machining technologies, combined with optimized toolpaths, can significantly reduce the time required for machining thin walls. By dynamically adjusting cutting parameters based on real-time data, manufacturers can minimize tool wear and reduce machining time. CAM software, such as Fusion 360, can assist in generating efficient toolpaths that maximize cutting speeds and minimize waste, resulting in reduced costs.

Real-time monitoring systems are invaluable for controlling quality and detecting potential issues before they affect part integrity. Sensors can track cutting forces, vibrations, and temperature fluctuations, allowing manufacturers to adjust machining parameters on the fly. This proactive approach helps prevent errors, reduce rework, and maintain consistent quality, ultimately lowering overall production costs.

Machining thin walls in CNC manufacturing can be challenging, but with the right strategies, costs can be minimized. Optimizing wall thickness, selecting the right materials, and using advanced techniques like multi-axis machining can significantly reduce production expenses. It's crucial for designers to balance strength, performance, and cost.

For further optimization and cost reduction, Onustec offers tailored solutions, helping you streamline production while improving your bottom line.

A: CNC machining of thin walls is difficult due to deflection, vibration, and tool wear, which increase machining time and cost.

A: To reduce costs, optimize wall thickness, select the right materials, and use larger tooling for efficient machining.

A: For metals, walls should be at least 0.8 mm thick, and for plastics, 1.5 mm, to avoid excessive machining time and costs.

A: Thin walls require multiple passes, increasing tool wear, which prolongs machining time and adds costs in CNC machining.

A: Multi-axis CNC machining reduces setup times and improves precision, leading to better efficiency and lower costs for thin wall machining.

A: Materials like aluminum alloys and certain plastics are easier to machine for thin walls due to their rigidity and machinability, reducing costs.