Views: 99 Author: Site Editor Publish Time: 2025-08-22 Origin: Site

Are you getting the most from your CNC machine? Selecting the right CNC tools and inserts is crucial for efficient operations. Choosing the wrong tools can lead to increased costs and reduced tool life. In this post, you'll learn CNC tool selection guide to select the best CNC tools and inserts for various operations, ensuring optimal performance and cost efficiency.

Selecting the right CNC tools and inserts requires careful consideration of several key factors. Understanding these will help you optimize machining performance, reduce costs, and extend tool life. This section of the CNC tool selection guide covers the essential criteria to evaluate when choosing tools for different operations.

The material you are machining heavily influences your CNC tooling choices. Different materials demand specific tool materials, geometries, and coatings to achieve the best results. For example:

Aluminum and soft metals: Use tools with sharper edges and polished flutes to prevent material buildup.

Steel and hardened alloys: Require tougher tool materials like carbide with coatings such as TiAlN to resist wear.

Plastics and composites: Benefit from tools designed to minimize heat generation and prevent melting.

Matching the tool to the workpiece material ensures efficient cutting and longer tool life. This is a critical step in the CNC insert selection process and overall tool selection criteria.

Tool geometry—such as flute count, helix angle, and cutting edge shape—affects chip evacuation, surface finish, and cutting forces. For instance, a higher helix angle improves chip removal in softer materials, while a lower angle suits harder materials.

Coatings enhance tool performance by reducing friction, increasing hardness, and improving heat resistance. Common coatings include:

TiN (Titanium Nitride): General-purpose, improves wear resistance.

TiCN (Titanium Carbonitride): Harder than TiN, good for abrasive materials.

AlTiN (Aluminum Titanium Nitride): Excellent for high-speed machining of hard materials.

Choosing the right geometry and coating is a vital part of how to choose CNC tools effectively.

Your CNC machine’s specifications also determine which tools you can use. Factors to consider are:

Spindle speed and power: High-speed spindles allow the use of smaller diameter tools and higher cutting speeds.

Tool holder compatibility: Ensure the tool shank matches the holder for proper rigidity.

Axis travel and clearance: Some tools require more space for effective operation.

Understanding machine limitations helps avoid tool breakage and suboptimal machining, aligning with CNC tool programming tips and tooling setup tips.

Balancing cost and performance is crucial. While premium tools and inserts may have higher upfront costs, their longer life and better performance can reduce overall production expenses. Consider:

Tool life expectancy: How long the tool can perform before replacement.

Cost per part: Calculate based on tool cost divided by the number of parts produced.

Maintenance requirements: Tools that are easier to maintain can save downtime.

This approach ensures you select tools that deliver value over time, a key element in CNC machining tool selection.

Tip: Always match your CNC tools and inserts to the specific material and machine capabilities to maximize tool life and machining efficiency.

Understanding the various CNC tools and their specific uses is key to mastering the CNC tool selection guide. Each tool type serves distinct functions in different machining operations. Knowing their applications helps you select the right CNC tool for different operations, improving efficiency and precision.

End mills are versatile cutting tools used primarily in milling operations. They come in various shapes and sizes, including square, ball nose, and corner radius types. End mills cut in multiple directions, making them ideal for slotting, profiling, contouring, and pocketing.

Square end mills: Best for flat-bottomed cuts and sharp corners.

Ball nose end mills: Used for 3D contouring and complex surface machining.

Corner radius end mills: Help reduce chipping and improve tool life.

Choosing the right end mill involves considering the material, geometry, and coating, which ties into the cnc tooling setup tips and the cnc insert selection process.

Drill bits are designed for creating holes and come in various styles such as twist drills, center drills, and spot drills. Each serves a unique purpose:

Twist drills: Standard for through-hole drilling.

Center drills: Used to start holes accurately and prevent wandering.

Spot drills: Create a precise spot for drilling, improving hole quality.

Selecting the right drill type and size is crucial in the cnc tool selection criteria to ensure hole accuracy and reduce tool wear.

Turning tools are used in CNC lathe machines to remove material from rotating workpieces. They come in various profiles like:

Straight turning tools: For general turning operations.

Profiling tools: For complex shapes and contours.

Threading tools: Designed to cut threads.

These tools often use replaceable inserts, making the cnc insert selection process vital. Proper selection improves surface finish and dimensional accuracy.

Boring tools enlarge existing holes with high precision. They are essential when tight tolerances and fine finishes are required. Boring bars and heads come in adjustable and fixed types.

Adjustable boring heads: Allow fine-tuning of hole diameter.

Fixed boring bars: Used for stable, repeatable boring operations.

Using the correct boring tool ensures accuracy in the cnc operation tooling guide and overall machining process.

Tip: Match each CNC tool type to its specific operation and material for best results, and always consider tool geometry and coatings to enhance performance and tool life.

Selecting the right inserts is a crucial part of the CNC tool selection guide. Inserts directly impact machining efficiency, surface finish, and tool life. Understanding insert grades, shapes, and coatings helps you tailor your tooling to specific operations and materials, ensuring optimal performance.

Insert grades refer to the material composition and hardness designed for specific machining conditions. Common grades include:

P-grade: For steel and general-purpose machining.

M-grade: Suited for stainless steel.

K-grade: Designed for cast iron.

N-grade: For non-ferrous materials like aluminum.

Choosing the correct grade reduces wear and improves cutting efficiency.

Insert shapes affect cutting geometry and chip flow. Popular shapes include:

| Shape | Description | Typical Use |

|---|---|---|

| CNMG | 80° diamond shape | General turning and profiling |

| TNMG | 55° diamond shape | Finishing and light roughing |

| WNMU | Trigon shape | Heavy roughing and interrupted cuts |

| CCMT | Rhombic 80° | Milling and turning |

The right shape depends on the operation and material, making this a key part of the cnc insert selection process.

Turning inserts must withstand high cutting forces and provide good surface finish. For turning:

Use P-grade inserts for steel parts.

Choose M-grade for tougher stainless steels.

Select CNMG or CCMT shapes for versatile turning.

Consider inserts with positive rake angles for better chip control.

Replaceable inserts simplify maintenance and reduce downtime, essential for efficient CNC machining tool selection.

Milling inserts differ in geometry and coating to handle multi-directional cutting. For milling:

Use K-grade inserts when working with cast iron.

Select WNMU shapes for roughing operations.

Choose CCMT or CNMG for finishing.

High-helix inserts improve chip evacuation in softer materials.

Milling inserts often have specialized coatings to withstand heat and abrasion during high-speed operations.

Coatings enhance insert durability and performance. Common coatings include:

TiN (Titanium Nitride): Improves wear resistance and reduces friction.

TiCN (Titanium Carbonitride): Harder than TiN, ideal for abrasive materials.

AlTiN (Aluminum Titanium Nitride): Excellent for high-speed machining and heat resistance.

Diamond Coating: Best for non-ferrous materials and composites.

Selecting the right coating extends tool life and improves surface finish, a critical aspect of the cnc tool selection criteria.

Tip: Match insert grades and shapes precisely to your machining operation and material to maximize tool life and machining quality.

Drilling requires tools designed to create precise holes efficiently. When selecting drill bits for CNC operations, consider:

Material compatibility: Use cobalt or carbide drills for harder metals; high-speed steel (HSS) drills suit softer materials.

Point angle: A 118° point angle works well for general-purpose drilling, while 135° is better for harder materials or thin-walled parts.

Coolant delivery: Choose drills with through-coolant capability to reduce heat and improve tool life.

Drill type: Twist drills are standard, but for accuracy, center drills and spot drills help start holes cleanly and prevent wandering.

Following this approach ensures hole accuracy and longevity, aligning with the cnc tool selection criteria and cnc tooling setup tips.

Milling operations involve cutting tools that can handle multi-directional loads. Key factors for milling tool selection include:

Tool shape: End mills are most common, with variations like square, ball nose, and corner radius to suit different cuts.

Flute count: Fewer flutes (2-3) improve chip evacuation in softer materials; more flutes (4+) provide better finish on harder materials.

Coating: AlTiN coatings excel in high-speed milling of hardened steels, while TiN suits general-purpose milling.

Tool diameter: Select size based on feature size and machine capability, considering spindle speed and rigidity.

This ensures efficient chip control and surface finish, critical in the cnc tool programming tips and cnc operation tooling guide.

Turning tools must withstand rotational forces and provide precise material removal. When choosing turning tools:

Insert type: Select inserts based on material and operation; for example, P-grade inserts for steel and M-grade for stainless.

Tool holder: Ensure compatibility and rigidity to minimize vibration.

Tool geometry: Positive rake angles improve chip flow; negative rake angles increase strength for tough materials.

Insert shape: CNMG and CCMT inserts offer versatility for roughing and finishing.

Choosing the right combination enhances surface finish and tool life, a key part of the cnc insert selection process.

Boring enlarges existing holes with high precision. Proper boring tool selection involves:

Tool type: Adjustable boring heads allow fine diameter control; fixed boring bars offer stability for repeatability.

Insert selection: Use inserts designed for boring with appropriate grades and coatings to handle the material.

Tool rigidity: Ensure the tool and holder provide minimal deflection for tight tolerances.

Machine compatibility: Confirm the boring tool fits within the machine’s clearance and spindle capabilities.

This attention to detail supports accuracy and finish quality, essential in the cnc machining tool selection and cnc operation tooling guide.

Tip: Always match your CNC tool and insert choices to the specific operation and material for optimal performance and cost efficiency.

Optimizing CNC tool performance is essential for maximizing efficiency, extending tool life, and ensuring quality results. This section of the CNC tool selection guide focuses on key strategies to get the most out of your tools and inserts during different machining operations.

Speeds and feeds directly influence cutting efficiency, tool wear, and surface finish. Properly setting spindle speed and feed rate helps balance material removal rate with tool life. Too fast, and you risk overheating and premature tool failure; too slow, and productivity drops.

Spindle speed (RPM): Adjust based on tool diameter, material, and coating.

Feed rate: Set to allow smooth chip formation without overloading the tool.

Chip load: The amount of material removed per tooth per revolution, critical for insert life.

Using reliable CNC tool programming tips and calculators can simplify this process. For example, G-Wizard software helps select optimal speeds and feeds tailored to your specific tooling and material, reducing guesswork.

Regular maintenance preserves tool integrity and prevents costly downtime. Key maintenance practices include:

Cleaning tools and inserts: Remove built-up chips and coolant residue after each use.

Inspecting for wear and damage: Replace or regrind tools showing excessive wear or chipping.

Proper storage: Keep tools dry and organized to avoid corrosion and damage.

Insert replacement: Change inserts before they impact part quality or cause tool breakage.

Following CNC tool and insert maintenance routines ensures consistent machining quality and longer tool life.

Modern CNC software plays a vital role in optimizing tool performance. Features include:

Simulation: Detect potential collisions or errors in tool paths.

Toolpath optimization: Minimize non-cutting moves and reduce cycle time.

Adaptive machining: Adjust feeds and speeds dynamically based on cutting conditions.

Tool life monitoring: Track tool usage and predict replacement timing.

Incorporating these capabilities into your CNC tooling setup helps achieve higher precision and efficiency.

Continuous evaluation of tool performance is necessary to maintain optimal machining. Consider:

Surface finish quality: Poor finishes may indicate dull tools or incorrect speeds.

Dimensional accuracy: Monitor parts to detect tool deflection or wear.

Tool wear patterns: Analyze wear to adjust feeds, speeds, or tool choice.

Cycle time: Aim for the shortest cycle time without compromising quality.

Adjusting parameters based on these observations aligns with best practices in the cnc machining tool selection process and enhances overall productivity.

Tip: Regularly monitor and adjust speeds, feeds, and maintenance routines to maximize CNC tool life and machining efficiency.

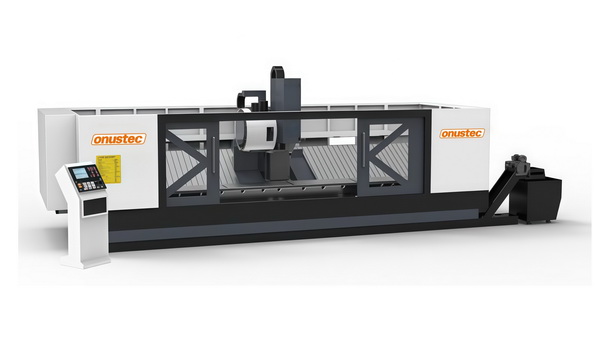

Selecting CNC tools and inserts involves key considerations like material type, tool geometry, and machine capabilities. Proper selection enhances machining efficiency and reduces costs. Continuously updating knowledge ensures optimal performance. Guangzhou Onustec Group Ltd. provides high-quality CNC tools that offer exceptional durability and precision, ensuring value and efficiency in machining operations.

A: The CNC tool selection guide emphasizes material type, tool geometry and coating, machine capability, and cost efficiency to optimize performance and extend tool life.

A: Material type dictates the choice of tool materials, geometries, and coatings, ensuring efficient cutting and longer tool life, which is crucial in CNC tool selection criteria.

A: Tool geometry affects chip evacuation, surface finish, and cutting forces, making it essential in CNC tooling setup tips for optimal machining performance.

A: Coatings reduce friction, increase hardness, and improve heat resistance, enhancing tool performance and longevity, vital in the CNC insert selection process.

A: Machine capabilities, like spindle speed and tool holder compatibility, determine suitable tools for efficient operation, crucial in selecting the right CNC tool.