Views: 0 Author: Site Editor Publish Time: 2026-01-15 Origin: Site

CNC machines(Computer Numerical Control machines) are transforming modern manufacturing with unmatched automation and precision. These machines can perform intricate tasks on metals, plastics, and wood, all while minimizing human error. In this article, we'll dive into the key components of a CNC machine. You'll learn how the CNC block diagram shows how these parts work together to achieve precise machining.

A CNC (Computer Numerical Control) machine is a tool that uses computer-generated instructions to automate the process of shaping materials. CNC machines are programmed using a specialized code, known as G-code, which tells the machine the specific movements and actions to take. There are two primary types of CNC machines: CNC mills and CNC lathes. CNC mills primarily work by rotating cutting tools against a stationary workpiece, while CNC lathes rotate the workpiece itself against a fixed tool. These machines are incredibly versatile, capable of handling everything from simple cuts to complex geometries.

CNC machines have dramatically transformed the manufacturing industry by automating tasks that once required significant manual effort. One of the key benefits is their efficiency—CNC machines can operate continuously with minimal oversight, significantly boosting productivity. Their precision allows for the creation of highly intricate parts that would be impossible with manual methods. Additionally, CNC machines reduce human error, providing repeatable accuracy for mass production or custom orders. They are widely used in industries such as automotive, aerospace, and medical device manufacturing, where precision and consistency are critical.

CNC machines are utilized across a variety of industries, with their most prominent applications being in the aerospace, automotive, and medical fields. In aerospace, they manufacture parts like turbine blades and engine components. The automotive industry relies on CNC machines to produce engine blocks, gears, and chassis components. CNC machines are also crucial in the medical industry, where they create implants, surgical instruments, and prosthetics with exceptional precision. The flexibility of CNC machines allows manufacturers to meet diverse production needs, from custom one-off designs to mass production.

The Machine Control Unit (MCU) is the "brain" of the CNC machine. It is responsible for interpreting the G-code commands and converting them into electrical signals that control the machine’s movements. The MCU coordinates the operation of the machine’s motors and tools to execute precise movements along multiple axes. It also manages other essential functions, such as coolant activation and tool changes, ensuring the machine operates smoothly and efficiently. The MCU is a critical part of any CNC machine, as it guarantees the machine follows the program's instructions accurately.

Input devices are how data, typically in the form of G-code, is loaded into the CNC machine. These devices can include keyboards for manual entry, USB drives to transfer completed programs, or wireless networks for downloading programs from other computers. The input device's role is crucial as it feeds the program into the MCU, enabling the machine to begin its operations. These input methods provide flexibility in how data is transferred and allow for easy updates and modifications to the machine’s operations.

The feedback system ensures the CNC machine operates with high accuracy by continuously monitoring its position and movements. Encoders and sensors are employed to track the actual position of the machine components, comparing them to the expected position based on the program instructions. This closed-loop feedback system allows the MCU to make real-time adjustments if any deviations occur, ensuring that every operation is performed within the desired tolerances. Feedback mechanisms are crucial for maintaining precision, particularly in high-accuracy applications like aerospace and medical manufacturing.

A CNC block diagram is a simplified visual representation of the CNC machine’s components and their interactions. It helps to understand how the machine’s various parts work together to execute the programmed instructions. In a typical block diagram, the main blocks include the input block (where data enters the system), the MCU block (where the program is interpreted), the drive system (which moves the machine components), the machine tool (which performs the machining), and the feedback system (which ensures the machine’s accuracy). The diagram provides a clear flow of how information is passed through the system, from input to operation.

The input block in a CNC machine represents the devices used to load the program into the system. These devices can range from computers and keyboards to USB drives or wireless connections. The purpose of the input block is to feed the G-code, which contains instructions for the machine’s movements, into the MCU. Once the data is entered, the MCU interprets the commands and sends instructions to the drive system, which translates them into physical movement. The efficiency of the input block is vital for ensuring that the CNC machine receives the correct program and performs the required operations.

The MCU block is the core component of the CNC block diagram, as it processes the incoming data and translates it into signals that direct the machine’s actions. The MCU receives input from the program, interprets it, and then controls the movement of motors, tools, and other parts of the CNC machine. It also manages auxiliary functions such as coolant activation and tool changes. The MCU ensures that the machine follows the program's instructions precisely, maintaining high levels of accuracy throughout the machining process.

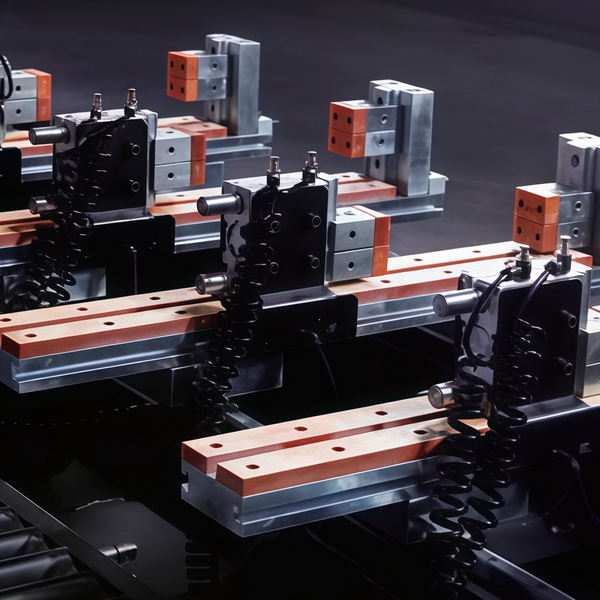

Servo motors are responsible for driving the machine components along the specified axes. These motors convert electrical signals from the MCU into mechanical motion, allowing the machine to perform cutting, drilling, and milling operations with high precision. Ball screws are used to convert the rotational movement of the servo motor into linear motion, ensuring that the machine components move accurately along the X, Y, and Z axes. Together, servo motors and ball screws form the backbone of the CNC machine’s drive system, allowing for precise and efficient machining operations.

| Parameter Category | Servo Motor | Ball Screw |

|---|---|---|

| Type | AC Servo Motor | High-precision Ball Screw |

| Application | Precision positioning, speed control | Converts rotary motion to linear motion |

| Accuracy | ±0.001 mm | ±0.002 mm |

| Rated Power | 1-10 kW | — |

| Speed Range | 1000-5000 rpm | — |

| Max Load | 100-1000 Nm | 10-2000 N |

| Efficiency | 90%-98% | 90%-95% |

| Material | Magnet, Copper | High-strength Steel, Aluminum Alloy |

| Maintenance Tips | Avoid overload, calibrate regularly | Regularly check lubrication, clean screws |

Linear guides are another critical component of the drive system, providing smooth movement along the axes and ensuring the machine components stay aligned. These guides help reduce friction and prevent deviations in the machine’s motion, contributing to the overall precision of the system. By maintaining the correct alignment of moving parts, linear guides help minimize errors and ensure that the machine performs within the desired tolerances. High-quality linear guides are essential for achieving the level of precision needed for tasks such as aerospace manufacturing and medical device production.

Calibration and synchronization improve CNC machine precision and reduce errors, ensuring parts meet high-quality standards. This table details how to calibrate your CNC machine efficiently.

| Calibration Item | Calibration Method | Calibration Frequency | Influencing Factors | Application Area |

|---|---|---|---|---|

| Axis Calibration | Use standard blocks | Every 6 months | Load, temperature changes | All CNC machines |

| Tool Calibration | Manual adjustment or probe | Every 1-2 months | Usage frequency, tool wear | CNC Mills, Lathes |

| Position Synchronization | Use sensors and feedback systems | Check weekly | Motor accuracy, load | High-precision machining |

| Motion Accuracy Calibration | Real-time encoder feedback | Every 3 months | Workpiece temperature, wear | Aerospace, Medical Parts |

| Feedback System Calibration | Use signal calibrators | Every quarter | Sensor accuracy, wear | High-precision CNC Mills |

Tip:Regular calibration ensures CNC machine components stay within specified tolerances, helping to maintain part quality and minimize errors.

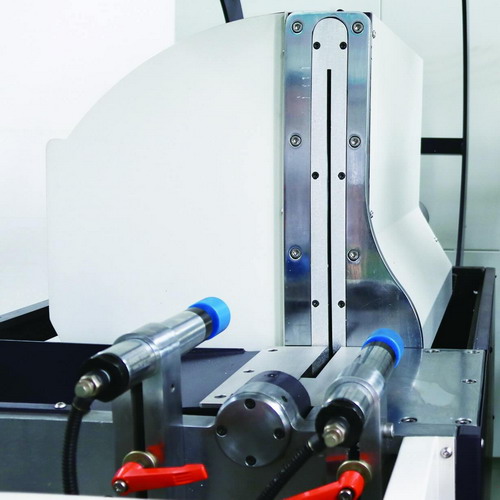

Machine tools are the parts of the CNC machine that actually perform the machining operations. These include cutting tools, spindles, and various attachments depending on the machine’s purpose. CNC lathes typically use stationary tools and move the rotating workpiece, while CNC mills move the rotating tools into the stationary workpiece. More advanced machines, like 5-axis CNC machines, can move both the workpiece and the tool to achieve even more complex shapes. The selection of the correct machine tool is crucial for achieving the desired part geometry and finish.

Tool holders are used to securely mount cutting tools onto the CNC machine, ensuring stability and precision during machining operations. Tool changers automatically swap tools in and out as needed, minimizing downtime and improving efficiency. With automated tool changes, the CNC machine can seamlessly switch between different cutting tools, allowing for complex multi-step processes without operator intervention. The use of tool changers is particularly advantageous in high-volume production, where efficiency and speed are essential.

5-axis CNC machines are designed to move both the tool and the workpiece simultaneously along multiple axes, enabling the production of intricate parts with complex geometries. This flexibility allows for machining operations that would be difficult or impossible with traditional 3-axis machines. In industries such as aerospace and automotive manufacturing, where parts often require multiple angles and complex features, 5-axis machines offer significant advantages in terms of precision and efficiency. By combining tool and workpiece movement, 5-axis machines reduce the need for part repositioning, leading to faster turnaround times and higher accuracy.

Cooling systems are crucial in maintaining the performance and longevity of CNC machines. This table will help you understand the different cooling systems' advantages and when to use them.

| Cooling System Type | Coolant Type | Efficiency | Recommended Application | Maintenance Requirements |

|---|---|---|---|---|

| Water-based Coolant | Water-oil mixture | High cooling capacity | High-strength metal machining | Regular coolant replacement |

| Oil-based Coolant | High-performance oils | Moderate cooling, good lubrication | Precision parts machining | Periodic oil quality check |

| Gas Cooling | Compressed air | Low efficiency, reduces contamination | Cleaning workpieces, light material machining | Regular air quality check |

| Spray Cooling System | Spray liquid | Continuous low temperature, reduces friction | High-speed cutting operations | Monthly system check |

| Built-in Cooling System | Internal circulation fluid | Optimal heat control, precise temperature | Multi-axis machines, high-precision lathes | Regular pipeline cleaning |

Tip:Choosing the right coolant type for your CNC machine’s operation is essential to ensure smooth and efficient performance, particularly in high-speed cutting.

Coolant systems play a critical role in extending the lifespan of cutting tools. By reducing the temperature at the cutting edge, coolant helps prevent premature wear and extends tool life. This is particularly important for high-speed machining operations, where the tools are subjected to significant heat and stress. In addition to preventing tool wear, cooling systems also improve the overall machining performance by maintaining consistent cutting speeds and reducing the risk of tool breakage.

Just as coolant helps extend the life of cutting tools, it also helps maintain the CNC machine itself. Regular maintenance of the cooling system ensures that the machine operates at peak performance, preventing overheating and reducing the risk of machine failure. Routine checks and maintenance of the coolant system, including changing coolants and cleaning the system, are essential for extending the life of the machine and ensuring reliable operation over time.

The bed of a CNC machine serves as the foundation for the entire system. It provides stability and support for the workpiece during machining operations. In CNC mills, the bed moves horizontally along the X and Y axes to position the workpiece accurately under the cutting tool. In CNC lathes, the bed holds the tool turret and tailstock, while the workpiece is held in place by the chuck. The stability of the bed is crucial for maintaining the accuracy and precision of the machining process.

The movement of the CNC machine’s bed is critical for achieving precise positioning of the workpiece. The bed moves along the X, Y, and Z axes, and in advanced 5-axis machines, it may also rotate to accommodate more complex parts. This movement allows the cutting tool to access different areas of the workpiece, ensuring that each operation is performed accurately. Proper alignment and movement of the bed are essential for minimizing errors and achieving high-quality parts.

In modern CNC machines, especially 5-axis machines, the bed may be designed to rotate along multiple axes, allowing for the machining of complex parts in a single setup. This rotational movement eliminates the need for repositioning the workpiece, reducing setup times and improving overall efficiency. The ability to customize the bed’s movement in advanced CNC machines allows for greater versatility in machining operations and is particularly beneficial for industries that require high-precision, complex parts.

The headstock in a CNC lathe houses the main drive, bearings, and gears necessary to rotate the workpiece during machining. The headstock is responsible for maintaining the rotation speed of the workpiece, ensuring that the cutting tool can shape the material accurately. The precision of the headstock’s rotation is critical for achieving smooth, accurate cuts, particularly when working with cylindrical materials.

The tailstock in a CNC lathe provides support for long cylindrical workpieces, preventing them from deflecting during the machining process. It is particularly important when machining parts like shafts or power screws. The tailstock can be moved along the Z-axis to accommodate different lengths of material. Its function is to keep the workpiece aligned, ensuring that it stays centered during the turning process.

Footswitches or pedals are used in CNC lathes to control the chuck and tailstock. These controls allow the operator to load and unload parts without needing to use their hands, improving workflow efficiency. While CNC mills do not typically use foot pedals, the use of these controls in lathes streamlines the operation by allowing the operator to focus on other tasks while maintaining control over key functions.

The control panel of a CNC machine allows the operator to interact with the machine, input commands, and monitor operations. It typically includes a display unit, a keyboard, and other control buttons. The control panel is often mounted on an extendable arm, allowing the operator to adjust its position for optimal access during machining runs. The layout and ergonomics of the control panel are crucial for efficient machine operation, particularly in high-volume production environments.

The control panel also includes input devices, such as a keyboard, and a feedback mechanism that allows the operator to monitor the machine's performance. The feedback system provides real-time data on the machine's status, such as its position and any errors. This allows the operator to make adjustments as needed, ensuring that the machine operates smoothly and stays on track.

The display unit provides critical information to the operator, including the current status of the machine, the G-code being executed, and any alerts or warnings. Some machines feature advanced touchscreen interfaces that allow the operator to edit programs directly from the display. The display unit plays a vital role in monitoring the machine’s operation, providing real-time insights that help maintain precision and prevent errors.

CNC machines are fundamental in modern manufacturing, offering unparalleled precision and efficiency. By reducing human intervention, they enable complex tasks on various materials. Understanding the key components and the CNC block diagram helps optimize machine performance. Guangzhou Onustec Group Ltd. provides high-quality CNC machines designed for industries like aerospace, automotive, and medical, offering reliable solutions that enhance production and precision. With their advanced systems, Guangzhou Onustec Group Ltd. ensures superior performance and value for manufacturers worldwide.

A: A CNC (Computer Numerical Control) machine is an automated tool that uses computer-generated instructions to perform tasks like cutting, drilling, or milling on various materials with high precision.

A: The CNC block diagram visually represents the flow of components within a CNC machine, illustrating how data moves from the input block to the machine control unit (MCU), which directs the drive system and feedback loops to execute precise movements.

A: The MCU is the brain of a CNC machine. It interprets the G-code and sends signals to control the machine’s motors and tools, ensuring the machine operates accurately and efficiently.

A: The input block in a CNC machine handles the data transfer, feeding the G-code instructions into the machine for execution. It ensures that the machine receives the correct program to perform the necessary tasks.

A: Servo motors and ball screws work together to convert electrical signals into precise mechanical movement, allowing the CNC machine to achieve accurate positioning along various axes for precise machining.

A: CNC machines reduce human intervention, minimize errors, and can run continuously, which speeds up production, ensures repeatable accuracy, and improves overall efficiency in manufacturing processes.

A: Troubleshooting a CNC machine involves checking for common issues like incorrect G-code, misaligned parts, or malfunctioning feedback systems. Regular maintenance and calibration ensure smoother operation and fewer errors.